COMPONENTS - ALUMINUM CONSTRUCTION FOR YOUR SPA, POOL AND PATIO ENCLOSURE

Aluminum sections developed especially for pool enclosures have a wall thickness from 1 to 3 mm, and are anodized or powder-lacquered (according to the RAL scale). The manufacturer (SAPA) is holder of the ISO 9002 certificate. We use 3 types of sections: 38×50, 60×63, 60×80 mm. The longest aluminum sections enable us to make a pool enclosure with a width up to 9 m – the smallest segment. For the largest enclosure structures, we use the Progres or Grande track with a height of 15 – 18 mm. The maximum segment width is 2,450 mm.

The structure of the swimming pool enclosure is filled with honeycomb polycarbonate: 10 mm, 8 mm or compact 4 mm panels. We use twin-wall or four-wall honeycomb polycarbonate. The polycarbonate panels cause the so-called greenhouse effect. Sunbeams dispersed in the atmosphere even on overcast days cause heating of the water and air in the closed enclosure. At night or on cold and cloudy days, the water and air cool down slower. The outer surface of all polycarbonate boards is covered in a high-quality UV stabilization layer, which absorbs the effects of harmful UV radiation and prevents impairment, cracking and unwanted color changes in the polycarbonate.

Properties of compact polycarbonate:

Compact 4 mm polycarbonate has much better optical properties than honeycomb polycarbonate. It can be used as the filling for the entire enclosure or for some parts only – e.g. front walls, side walls, etc.

Twin-wall polycarbonate is supplied in four colors:

Properties of four-wall polycarbonate:

Four-wall polycarbonate increases the thermal insulation by 13 % (in comparison with twin-wall polycarbonate).

TELESCOPIC SLIDING SEGMENTS FOR YOUR HOT TUB, POOL OR PATIO ENCLOSURE

Mobile swimming pool enclosures are constructed with telescopic sliding segments. Depending on the option chosen, the segments may be moved independently in both directions or as a single synchronized telescopic system.

The profiles come from renowned aluminum presses. The main producer is the Swedish company SAPA Group (plants in Sweden, Poland and Slovakia). The design solutions used in the IPC Team system – particularly the double walls hiding most of the rivets and bolts, automatic anchorage system, end wall solutions with hinged lower sections, very flat, low and elegant ground rails, automatic segment movement with remote control, and the attractive appearance of the end product – place our products among the best in Europe.

Construction solution

- The segments of a swimming pool enclosure can be moved in both directions; as required they can be moved telescopically to the end of the swimming pool or spread to cover the water surface. A retractable swimming pool enclosure makes it possible to use the pool even during bad weather. The other benefit of mobility is that on warm sunny days you can still enjoy the pleasure of using an uncovered swimming pool. There is no need to fit special air-conditioning systems.

- The entrance to the pool or spa enclosure may be a swinging door (with or without a brush bottom) or sliding door (with brush bottom). The doors may be single or double. The standard width of a single door is 32-36 inches. In the side of most segments it is possible to place a sliding door, which may serve either as an additional entrance or as an alternative to a door in the front wall, especially in the case of low enclosures.

- Another method of providing access to swimming pool enclosures is to construct the lower side walls with vertically sliding polycarbonate panels.

- In large or dome-shaped enclosures windows may be fitted to improve ventilation.

- If there is an obstacle, for example a pool ladder, hydro jet, or raised pool edge, the enclosure is provided with a hinged lower wall section of front/back wall which can be lifted in order to slide the enclosure section over the obstacle.

- The maximum width of some models of IPC pool enclosure is up to 45 feet.

POLYCARBONATE PANELS

The swimming pool and spa enclosures are fitted with 8mm or 10mm thick polycarbonate panels (solid, twin-walled or triple-walled). There are four colors of transparent/translucent polycarbonate panels available: clear, light blue, milky, and brown. Customers often choose 4mm thick solid polycarbonate panels which have clear-glass optical properties.

- Polycarbonate is a unique engineering thermoplastic which combines a high level of mechanical, optical, thermal and electrical properties. Multiwall polycarbonate features a proprietary surface treatment which provides resistance against degradation caused by UV radiation in sunlight.

- The enclosure frames are fitted with 8mm or 10mm twin wall or 4mm solid polycarbonate panels.

- The polycarbonate panels act like a greenhouse. Direct exposure to the sun’s rays or, on cloudy days, the effect of diffused rays still heats the air within the enclosure. At night or on cool, cloudy days the heat of the enclosed at atmosphere is slowly lost.

- The external surface of the polycarbonate has a layer of high-quality UV absorber, which blocks harmful UV radiation and prevents discoloration, crumbling and weakening.

- There are four colors of transparent/translucent polycarbonate available: clear, light blue, milky and brown.

- 4mm thick solid polycarbonate panels (made by Palsund Ltd., England) have much better optical properties than cellular polycarbonate. They can be used either throughout the structure or only in selected parts of the enclosure (for example, for the end walls or one chosen wall).

Features

- The swimming pool, spa, or patio enclosure has high strength in relation to its weight

- Good insulating properties due to its multi-wall structure (up to 60% better than glass plates)

- High level of sound damping - up to 25dB(A)

- Impact Resistance - 200 times better than glass

- Excellent Weather Ability

- Fair Abrasion Resistance

- Excellent Temperature Resistance

- Good Chemical Resistance

- Excellent Degrees of Light Transmission

- Flammability Resistance

- Excellent Clarity

- UV resistance (surface UV filter)

ALUMINUM PROFILES

The framework of the structure consists of aluminum profiles. The aluminum construction is filled out with polycarbonate panels.

Special Construction Profiles

- The engineers used special materials with high thermal expansion at both high and low temperatures when designing the free movement of the segments. For years we have been improving the mechanism used to secure the swimming pool and spa enclosures in strong winds and the top-quality automatic anchoring system. The materials and techniques used enable the building of free standing enclosures up to 45 feet wide. The length of the structures is unlimited.

- Our aluminum comes from renowned aluminum presses, mainly SAPA Aluminum (Sweden, the main producer), YAWAL Czestochowa (Poland) and Alufinal (Slovakia). These companies guarantee that our aluminum profiles are always of the highest quality and that the dimensions of each wall of a profile are perfectly uniform. This means that our profiles offer maximum durability with minimum thickness and optimum aesthetic qualities.

- The aluminum profiles are fully anodized or powder painted (according to the RAL palette). The producer (SAPA) holds an ISO 9002 certificate. In view of the available technical facilities, the longest profiles are anodized in France or Germany to ensure that the surface is perfectly uniform.

Materials

- The construction of the pool and spa enclosures is based on specially designed aluminum sections (ALMGSI 0.5/F22 alloy; wall width 1.5-3.0mm). The individual rails and braces in the sections are designed to provide maximum static strength.

- All joints of the aluminum sections are hidden, so there are no visible joints or rivets.

- The ground rails are anodized or powder-painted.

- The aluminum structure is fitted out with panels made of clear or twin-walled polycarbonate, which significantly increases the strength of the light construction and ensures better heating and insulation properties (not available when glass is used).

- 10mm thick polycarbonate is used for a more rigid structure. The sides and ends can be fitted with 4mm material (single-walled, solid polycarbonate) if required. The Oceanic model is always glazed with single-walled polycarbonate in the sides and ends.

- To seal the space between the segments (which is 1.5 inches wide) we use silicon strips. The space between the end wall and the ground is fitted with brushes, which means there is no need to remove the wall when it has to be moved over obstacles (maximum height 6 inches). If the pool has elements which are higher than this, the lower section of the end wall can be hinged to enable it to be raised.

- Normally the maximum length of a segment is 7 feet.

Construction Profiles

- We use four types of profiles: 38×50, 38×60, 60×63 and 60×80mm.

- The largest aluminum profiles allow construction of free standing swimming pool enclosures in which the segments are up to 45 feet wide.

- The largest structures use Grande ground rails (18mm high).

Wind Load

- The anchoring system of each segment for wind load consists of 2 elements made of A2 stainless steel.

SLIDING SYSTEMS

Sliding systems consist of polyamide rollers with stainless steel bearings. Segments of the enclosures slide easily on ground rails.

- Our state of the art ground rail is 5/8th of an inch thick. It is flat, low, easy to walk on, provided with an anti-slip surface and allows safe movement around the swimming pool as well as the very simple sliding of the enclosure segments.

- The ground rails are silver anodize aluminum sections, so there are no sharp exposed edges (as is the case with the exposed rails of some manufacturers).

- Ground rails can be attached to even surfaces, horizontally or vertically or obliquely on the walls of buildings.

- The number of tracks on the ground rails corresponds to the number of segments making up the swimming pool enclosure. You may extend the ground rails past your pool so as to slide the enclosure completely off and away from your pool.

- In rectangular enclosures it is possible to have the segments slide electronically (powered from the mains or by solar energy).

Extreme Wind Protection

- A docking system made of stainless steel A2 plates (fixed to the lower aluminum profiles of the segments) and “Docking Stop” element (fixed to the ground) provides added protection from the enclosure being lifted by strong winds.

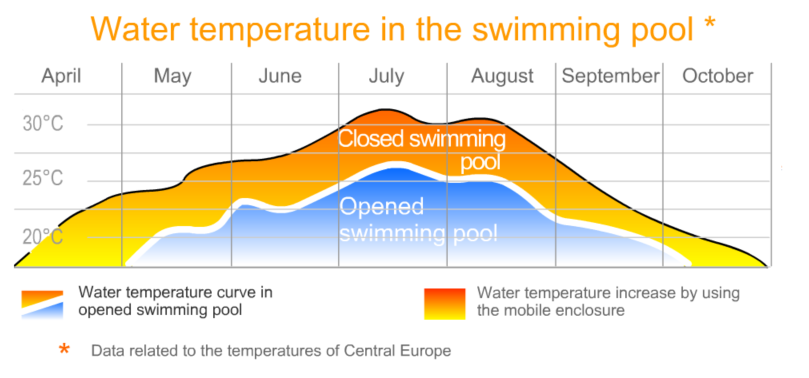

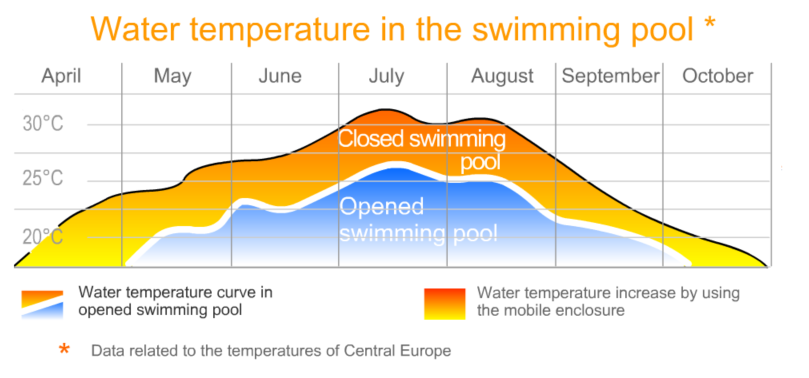

WATER TEMPERATURE

CARE AND MAINTENANCE

The enclosures are designed to satisfy the rules for permitted development. However, under certain circumstances (this especially applies to enclosures constructed with some or all sections fixed) planning consent may be required. In such case a consultant engineers calculations are available on request.

Sliding the segments

- An enclosure consists of segments which can be moved on rails in both directions. The segments should be moved by two people, one on each side, otherwise – especially in the case of wide enclosures – a jam may occur.

Resistance to External Conditions

- The swimming pool, spa, or patio enclosure is resistant to normal outdoor conditions – moisture, sunlight, rain/snow fall, low and high temperatures as well as conditions inside the enclosure (higher humidity, presence of pool chemicals in water and vapor). However, the structure must not be exposed to open fire, very high temperatures, acids or reactive liquids (especially in high concentration) because there is a risk of damaging the polycarbonate panels. Mechanical loads on the structure or panels may cause damage or affect the functionality of the enclosure.

Cleaning

- The polycarbonate has to be cleaned regularly in order to remove dirt from the surface. In most cases it is sufficient to rinse it with a stream of water. In case of heavy dirt it should be wet with clean water and then cleaned with a soft cloth or extensible mop and a detergent, with frequent rinsing. The water should be frequently changed and the cloth or mop should be kept clean and free of grains of sand.

- Cleaning pastes should not be used, as they may cause scratches on the polycarbonate surface. Also to be avoided are solvents containing benzene, petrol or acetone or basic washing powders. It is recommended that the plates not be cleaned when they are hot, for example due to exposure to sunlight.

- Do not use sharp tools to clean the enclosure

Protecting the enclosure against strong winds

- If all the above mentioned conditions are met the unique coupling system of mobile segments will ensure the structure is secure in strong winds

- To prevent the enclosure from being lifted by a strong wind, the user should fully extend the enclosure, close all doors and windows, and anchor the segments to the ground. The end wall bolts should also be inserted into special anchoring holes in the ground.

Protecting against heavy snow

During winter, snow should not be allowed to accumulate on the enclosure in large quantities. Large enclosures are most at risk. If a thick layer of snow is left on the top surface of the enclosure, damage may occur.

Maintenance of the enclosure

The structure is resistant to corrosion, and apart from rinsing with water, does not require additional work. Only the hinges and door-lock require maintenance. By lubricating these parts you will ensure that the structure continues to function properly for a long period

Product Warranty

All materials not manufactured by the manufacturers of the IPC association are limited to the warranty provided by the manufacturers. THIS LIMITATION SUPERSEDES AND RESTRICTS ANY WARRANTY PROVIDED BY ALL MEMBERS OF IPC.

This limited warranty does not cover damage or defects resulting from misuse, accident, alteration, negligence or lack of reasonable and proper maintenance, nor does it cover delays or construction costs due to damaged delivery.

The obligations of the IPC manufactures under this limited warranty are limited to the repair or replacement, at the Company’s option, of defective parts of their products.